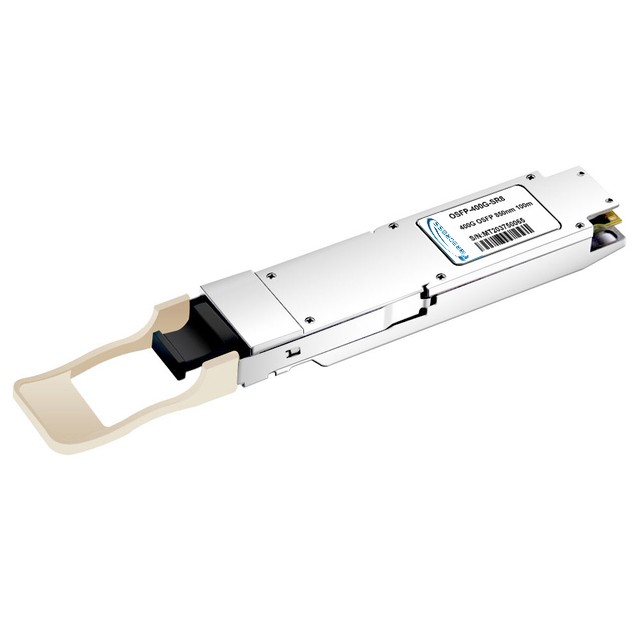

How 400G Transceiver Testing Ensures Optical Module Quality?

Introduction: Why 400G Testing Matters

With the explosion of cloud computing, AI workloads, and 5G deployments, the demand for ultra-high-speed data transmission is surging. As a result, 400G optical transceivers have become a backbone technology for modern data centers and telecom networks.

However, achieving this level of performance isn’t just about pushing more bandwidth—it’s also about ensuring reliability, interoperability, and long-term stability. That’s where rigorous 400G transceiver testing comes in. Each module must pass a suite of quality checks to avoid costly failures and ensure flawless operation in high-density environments.

At Fibrecross, testing isn’t an afterthought—it’s a core part of our promise to deliver high-performance, fully compliant optical modules.

Common Quality Challenges in High-Speed Optical Modules

Testing is necessary because 400G transceivers are susceptible to several potential issues:

Interoperability concerns: Compatibility with various switch and router vendors must be guaranteed.

Thermal sensitivity: Higher data rates generate more heat, increasing the risk of overheating or power imbalances.

Signal distortion: PAM4 modulation introduces more vulnerability to noise, jitter, and inter-symbol interference.

Component inconsistency: Manufacturing variations or counterfeit parts can lead to unpredictable behavior.

Performance drift over time: Optical and electrical components can degrade under prolonged operation.

To mitigate these risks, each 400G transceiver must undergo comprehensive testing under real-world conditions.

Core Testing Procedures for 400G Optical TransceiverModules

At Fibrecross, every 400G module undergoes several stages of validation. Here’s what the process typically involves:

1. Interoperability Testing

Fibrecross tests transceivers across multiple mainstream platforms, including switches and routers from different vendors. These plug-and-play evaluations help ensure that our modules conform to industry-wide protocols like IEEE 802.3bs/cd and relevant Multi-Source Agreements (MSAs), such as QSFP-DD and OSFP.

This step is essential to avoid network link failures or communication mismatches during deployment.

2. Eye Diagram and Jitter Analysis

A critical part of signal integrity testing involves analyzing the eye diagram—a visual representation of digital signals. A “clean” eye indicates minimal noise and accurate signal timing. In contrast, a blurry or closed eye means potential data corruption.

Fibrecross uses high-speed oscilloscopes to verify signal quality and timing margins, ensuring the transceiver maintains data fidelity even at 400G speeds using PAM4 modulation.

3. Bit Error Rate (BER) Testing

BER testing simulates real network traffic using pseudo-random data patterns. The pre-FEC (Forward Error Correction) bit error rate must remain within specified limits to ensure that any minor errors can be corrected during normal operation.

A low BER is a direct indicator of the module’s stability under load, especially over extended periods.

4. Optical Power and Extinction Ratio (ER) Validation

Each transceiver’s transmitter is evaluated for:

Output optical power – to ensure signal levels are within operational ranges.

Extinction ratio (ER) – to measure the contrast between “on” and “off” signals in a data stream.

A strong ER and consistent optical power indicate reliable transmission, reducing the risk of signal degradation in the field.

5. Wavelength Accuracy and Spectrum Analysis

For wavelength-specific modules (e.g., LR4, FR4), precision matters. Spectrum analysis verifies that the laser operates at the correct central wavelength and maintains high side-mode suppression ratios (SMSR). This minimizes interference and ensures compatibility with wavelength-division multiplexing (WDM) systems.

6. Environmental and Stress Testing

Fibrecross subjects each transceiver to environmental extremes, including:

Thermal cycling across the full operating range (e.g., –20°C to +85°C)

Humidity and vibration tests to simulate real-world installation conditions

Aging tests to detect potential failure points over time

These stress tests are critical for optical module quality assurance, especially for modules deployed in outdoor or industrial settings.

Compliance with Industry Standards

Adherence to international standards is not optional—it’s mandatory for market acceptance. Fibrecross transceivers are tested according to:

IEEE standards (e.g., 802.3bs for 400GBASE-SR8, FR4, etc.)

MSA specifications (e.g., QSFP-DD, OSFP)

CMIS (Common Management Interface Specification) for module monitoring and diagnostics

These compliance checks guarantee multi-vendor interoperability and smooth integration into any standards-based network architecture.

Real-World Impact of Testing and QA

Why does this testing matter beyond the lab?

Reduced risk of failure: Thorough testing prevents defective modules from entering your network.

Stable performance under load: Network engineers can count on consistent throughput and low latency, even in high-traffic scenarios.

Longer product lifespan: Modules that pass thermal and aging tests are less likely to fail prematurely, reducing maintenance costs.

Operational confidence: Data center and telecom operators can deploy with peace of mind, knowing their infrastructure won’t suffer from hidden flaws.

Why Fibrecross 400G Transceivers Are Trusted

At Fibrecross, quality assurance is embedded into every stage of production. Our 400G transceivers are:

Individually tested for interoperability, signal integrity, and error performance

Certified against IEEE and MSA standards

Stressed under real-world environmental conditions

Monitored with precision tools to validate laser performance, optical power, and timing

This rigorous approach ensures that every Fibrecross module delivers top-tier performance from day one—whether it’s deployed in hyperscale data centers, carrier networks, or enterprise backbones.

Conclusion: Quality You Can Deploy With Confidence

As networks evolve toward faster, more complex topologies, transceiver performance becomes even more critical. Testing isn’t just about meeting technical specs—it’s about ensuring operational excellence in real-world deployments.

Fibrecross 400G transceivers are designed and tested with one goal in mind: reliable, high-speed data transmission you can trust.

If you’re looking for scalable, dependable optical solutions backed by rigorous QA, choose Fibrecross.