Advanced Troubleshooting Guide for Optical Transceivers (2025 Edition)

Technical Summary

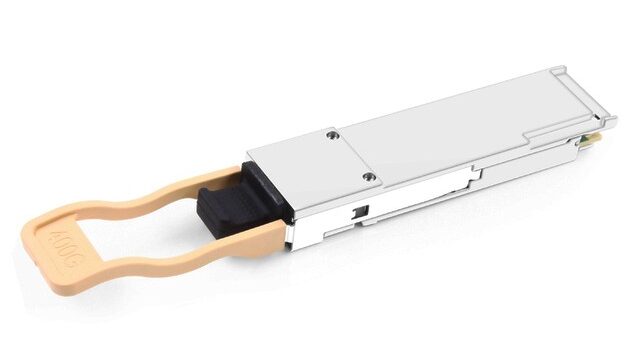

Optical transceivers—such as SFP, QSFP, and OSFP transceivers —are essential components in high-speed data center and enterprise networks. These fiber optical transceivers convert electrical signals into light and back, enabling long-range, high-bandwidth communication over fiber optic links.

As networks evolve to support 400G/800G optical transceivers, fault diagnosis has grown more complex. Technicians now require advanced tools like bit error rate testers (BERT), signal integrity analyzers, and real-time DDM monitoring. This guide provides a deep technical overview of how to troubleshoot sfp optical transceivers and other optical transceivers module types effectively in 2025.

Common Transceiver Symptoms

Link down or unstable

Frame check sequence (FCS)/CRC errors

Intermittent packet drops or retries

Unsupported module or “unqualified optic” messages in logs

Common across many environments, these issues often point to problems in the fiber optical transceivers, cables, or port configuration. As bandwidth requirements increase—especially with the adoption of 400G/800G optical transceivers—even minor link degradations can impact network performance.

Root Causes of Transceiver Failures

Environmental & Mechanical Factors:

SFP optical transceivers and high-speed modules are sensitive to environmental conditions. Excessive temperature, humidity, dust, or physical mishandling can damage a transceiver’s laser or optics. Poor airflow or insufficient cooling often leads to thermal degradation.

Optical Path and Link Quality:

Every optical transceivers module relies on clean, properly connected fiber. Excessive loss, reflection, or connector contamination can reduce received optical power below the module’s threshold, causing link instability.

Recommended Tools for Diagnosis

| Tool | Function | Use Case |

|---|---|---|

| Optical Power Meter | Measures TX/RX power levels | Validate optical link budgets |

| DDM/DOM Reader | Monitors laser bias, temperature, power | Detect degrading fiber optical transceivers |

| BERT Tester | Analyzes bit error rate (BER) | Evaluate high-speed (400G/800G) links |

| Fiber Scope | Inspects connector endface | Identify contamination or scratches |

| OTDR | Tests fiber continuity | Locate bends, breaks, or splices |

These tools are critical when working with sfp optical transceivers, especially in dense environments like multi-vendor data centers or hyperscale cloud platforms.

Step-by-Step Troubleshooting Method

Inspect Physical Connection

Ensure the optical transceivers module is seated correctly and the connectors are clean. This simple step resolves many issues with sfp optical transceivers in access switches and core routers.Swap and Isolate

Test with a known-good module or patch cable. If the issue persists, suspect either the switch port or external fiber path.Check Digital Diagnostics (DDM)

Read TX/RX power, bias current, voltage, and temperature. Fiber optical transceivers nearing end-of-life often show abnormal bias currents or low transmit power.Analyze Logs

Look for messages like “link down,” “FEC corrected errors,” or “unsupported optic” to pinpoint compatibility or performance issues.Review Configuration and Firmware

Ensure switch settings match the transceiver’s capabilities. 400G/800G optical transceivers may require specific FEC modes or firmware revisions to function correctly.

Multi-Vendor Compatibility Best Practices

Using non-OEM optical transceivers module types can introduce compatibility challenges. Vendor-locked ports may reject third-party optics unless correctly coded.

Always verify module support in your switch/router’s compatibility list.

Use MSA-compliant sfp optical transceivers for standardization.

Ensure fiber optic specifications match: single-mode vs. multi-mode, wavelength, and power budget.

Predictive Maintenance Strategies

A proactive approach to maintaining optical transceivers improves uptime and reduces surprise outages.

Enable DDM Monitoring: Continuously track temperature and power trends across all installed fiber optical transceivers.

Analyze Trends: Use automation to detect anomalies like rising bias current or decreasing RX power—signs of aging optical transceivers module hardware.

Schedule Replacement: Replace sfp optical transceivers nearing end-of-life or showing performance drift.

High-Speed Troubleshooting (400G/800G Optical Transceivers)

Modern optical transceivers supporting 400G/800G speeds are highly sensitive to loss, jitter, and reflection. Signal integrity issues or incorrect FEC configurations can lead to silent bit errors or flapping links.

Best practices include:

Use BERT tools to validate pre-FEC and post-FEC error rates.

Confirm compatibility of QSFP-DD and OSFP 400G/800G optical transceivers with host equipment.

Audit cable quality and connector polish to minimize reflections.

Best Practices Summary

Clean all connector interfaces before connecting fiber optical transceivers.

Maintain updated compatibility matrices across your vendor hardware.

Monitor and log DDM parameters for early failure detection.

Handle all sfp optical transceivers with ESD protection and use dust caps when not in use.

Train staff on correct optical maintenance and inspection procedures.

Conclusion

Troubleshooting optical transceivers in 2025 requires deep understanding of module behavior, compatibility, and signal diagnostics. Whether you’re working with traditional sfp optical transceivers or deploying high-density 400G/800G optical transceivers in hyperscale networks, a disciplined, data-driven approach ensures maximum reliability and performance.

By combining proactive monitoring, quality components, and structured troubleshooting, technicians can extend the lifespan of every optical transceivers module and prevent costly network outages.